Efficient driving and fantastic driving comfort with I-Shift Dual Clutch

Travelling up steep hills with a fully loaded truck, over ice and on bumpy roads where the ground frost is just starting to melt – these are everyday driving conditions for Lars Lindgren. Every week, he transports general cargo between the city of Luleå in northern Sweden and various destinations in Norway. Lars Lindgren was one of the drivers who have tested the I-Shift Dual Clutch transmission before its’ launch in 2014. “The first time I drove a truck with the Dual Clutch transmission, I was incredibly impressed. As you are driving, you don’t even notice when the truck changes gears,” he says and looks out over the Norwegian landscape.

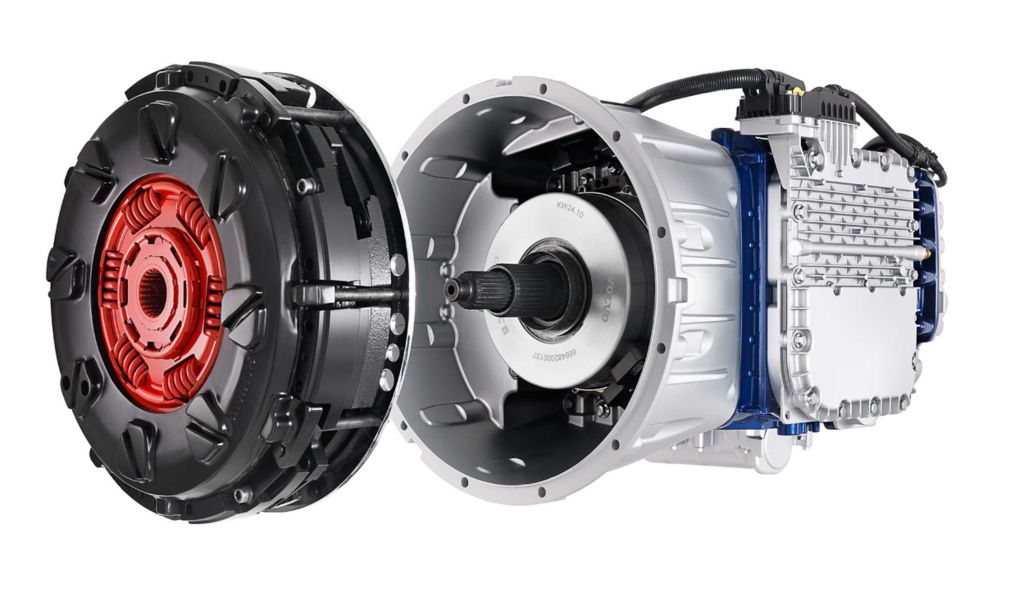

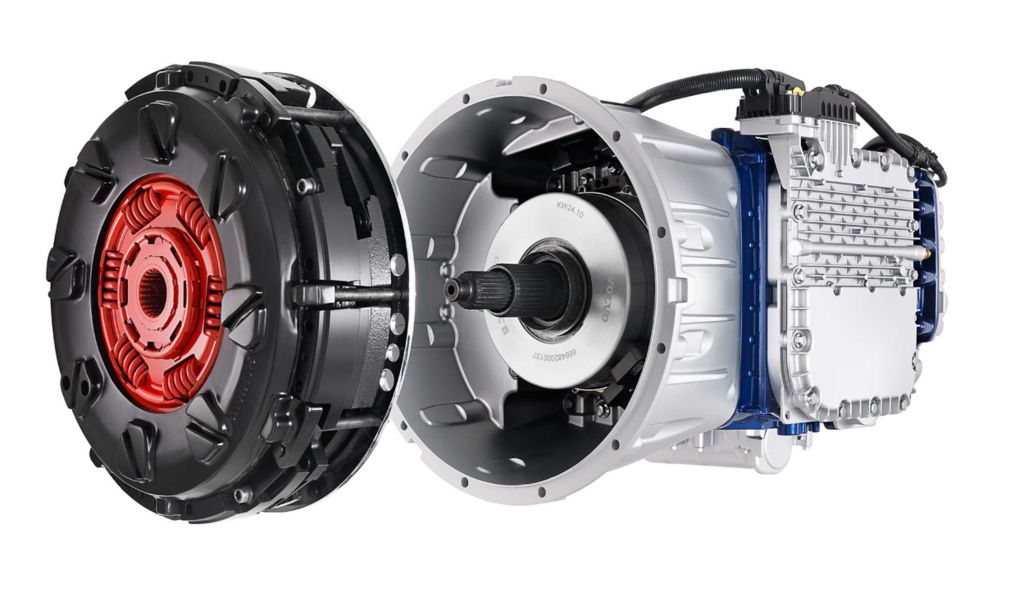

The I-Shift Dual Clutch can basically be described as two transmissions combined in parallel, each with a separate clutch. “Put simply, you could say that one gearbox controls the even gears, while the other manages the odd ones. When a gear is active in one gearbox, the next gear is prepared in the other gearbox. When the truck changes gear, no speed is lost during the actual gear change,” explains Astrid Drewsen, Volvo Trucks. As the truck does not lose any power, driving in environments that require a large amount of gear changing is both more efficient and more convenient. “On steep hills, on winding roads and on roads where it is easy to get stuck, I-Shift Dual Clutch, developed for long-haul applications, is absolutely fantastic. For example, once you've got going with a full load in the middle of the forest, you don’t want to risk getting stuck because the truck changes gear. With the I-Shift Dual Clutch, the truck simply takes off and gear-shifting is seamless,” Astrid Drewsen adds. The I-Shift Dual Clutch changes gear whenever necessary, with no loss of power.

On steep hills, on winding roads and on roads where it is easy to get stuck, this new gearbox is absolutely fantastic.

Great driveability and enhanced driver comfort

In driving when it is more advantageous that the gearbox skips a few gears, the gearbox changes gear like a standard I-Shift. The I-Shift Dual Clutch can change gear with no torque interruption on every gear apart from range gear shifting, which takes place between gears 6 and 7. In addition to driveability, driver comfort is also enhanced. The environment in the cab is perceived as being quieter, and the smooth driving makes the driver less tired. “The smooth ride enabled by the seamless gearchanging is also sympathetic to the vehicle and the cargo. Uneven driving results in wear and tear, not only to the driver and the driveline, but also to the whole vehicle. If you are transporting livestock or driving a tanker containing liquid, the less the cargo moves about, the better,” says Astrid Drewsen.

First tests in the 1990s

The technology involved in dual-clutch transmission is nothing new. It has been used, especially in performance cars, for quite some time. Volvo Trucks actually began considering a transmission with a dual clutch over 25 years ago. “In the 1990s, we tested a gearbox with a dual clutch, but it was only a prototype with a whole raft of add-ons that would never have worked in practice or been feasible in series production,” explains Björn Lyngsö, Volvo Trucks. The greatest problem when it comes to adapting dual-clutch technology to trucks is that trucks are driven in such varied conditions and in different environments – on everything from small, winding forest roads to motorways. The transmission needs to work equally well when the truck is empty and fully loaded. It needs to withstand extreme heat and cold and continue running for thousands of miles without causing problems. So a large part of the work on the I-Shift Dual Clutch involved testing and optimising hardware and software until the engineers were really sure that the transmission would function in every situation and in all conditions – 365 days a year.

2007, the launch of Volvo I-Shift Dual Clutch

In 2007, Volvo Trucks took the first steps towards the I-Shift Dual Clutch. The fact that the I-Shift has been a market leader among automated transmissions for heavy trucks since 2002 was an essential factor when it came to developing the I-Shift Dual Clutch. “The development teams behind both the software and the hardware in the I-Shift Dual Clutch comprise the same people who worked on developing the I-Shift. Without the knowledge and experience we acquired from developing the I-Shift, we would never have been able to develop the I-Shift Dual Clutch,” explains Björn Lyngsö. On the outside, the I-Shift Dual Clutch looks like a standard I-Shift. The only difference is that the front part of the transmission is 12 centimetres longer. The rear of the transmission is almost identical to the rear of the I-Shift and the power take-offs are the same. On the inside about 100 of the more than 300 components in (the new transmission) I-Shift Dual Clutch are different compared with the I-Shift.

With I-Shift Dual Clutch the truck keeps an even speed and the tyres maintain a constant grip on the road surface. It feels safe to drive on winter roads when you know that the tyres won’t lose traction.

The inside of I-Shift Dual Clutch can be compared to a sophisticated jigsaw puzzle, where every single millimetre has been used and every component has been optimised to take up as little room as possible. “It’s fantastic that we have succeeded in incorporating all the functionalities in just 12 centimetres. This required a great deal of ingenuity,” says Björn Lyngsö. In northern Norway test-driver Lars Lindgren sits calmly and securely behind the wheel, as his truck, a Volvo FH with an output of 540 horsepower, begins the climb up one of the steepest hills in the area. Some hills here have a gradient of 10 per cent – a real challenge for a fully-loaded 48-tonne truck.

“With I-Shift Dual Clutch the truck keeps an even speed and the tyres maintain a constant grip on the road surface. It feels safe to drive on winter roads when you know that the tyres won’t lose traction,” he says. With I-Shift Dual Clutch, Lars Lindgren says that the truck is much smoother both on country roads and when driving in the city. “I have been driving trucks since 1979 and have trouble with my shoulders and neck. The fact is that since I started to drive with I-Shift Dual Clutch I don’t notice these problems anymore. That’s fantastic,” he says. As no power is lost during gear changes, the truck maintains a steadier and higher speed, even on roads where the driving conditions are challenging. I-Shift Dual Clutch also improves downhill driving, as there is no loss of engine braking during gear changes. “I can save 10 minutes during a four-and half-hour shift. That’s a lot of time when you add it up over a whole working week.”

How it works - I-Shift Dual Clutch

The seamless gear change with the I-Shift Dual Clutch is made possible by the gearbox’s two clutches and input shafts. Learn more about I-Shift Dual Clutch in this episode of ‘One Minute’ – the mini series that covers interesting topics for all truck enthusiasts, and all within one minute.